SELF PRIMING MUD PUMPS (IMH-IMS Series)

TECHNICAL SPECIFICATIONS

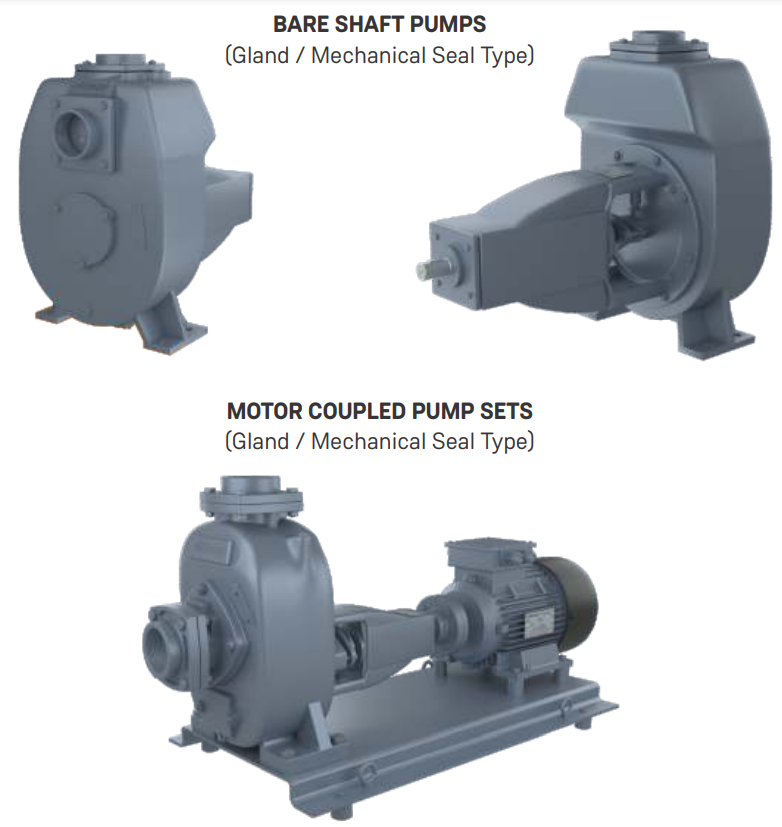

Types :

Bare Shaft Pumps (Gland & Seal Type)

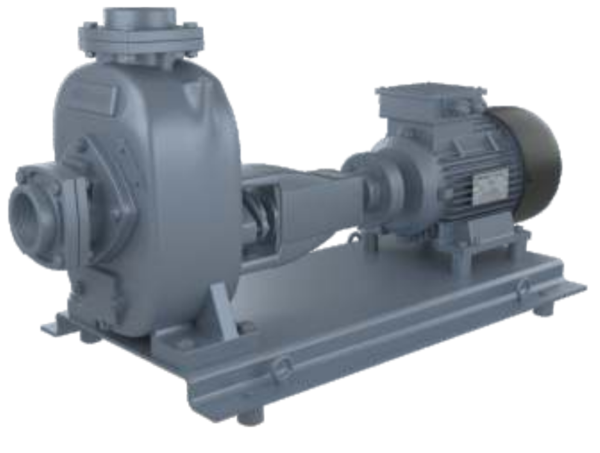

Motor Coupled Pump Sets (Gland & Seal Type)

Engine Coupled Pump Sets (Gland & Seal Type)

Monoblock Pump Sets (Gland & Seal Type)

Motor Hp (Kw) : 1.00 (0.75) to 25.00 (18.70)

Pipe Size (Mm) : 40 X 40 to 150 X 150

Speed (Rpm) : 1440 & 2800

Head (Mtrs) : Up to 44

Discharge (Lps) : Up to 71

Solid Handling Size (Mm) : Up to 40

MATERIALS OF CONSTRUCTION

REGULAR SUPPLY

Pump / Motor Body : C. I. Gr. FG 200

Impeller : C. I. Gr. FG 200

Wear Plate : C. I. Gr. FG 200

Impeller Ring : C. I. Gr. FG 200

Shaft : SS-410

Shaft Sleeve : SS-410

Stamping : CRNGO, M-45 Grade

Gland Packing : Graphite asbestos

Bearings : SKF / Equivalent

OPTIONAL SUPPLY

Impeller : SS-304 (CF 8) / SS-316 (CF 8M) / Bronze

Impeller Ring : SS-304 (CF 8) / SS-316 (CF 8M) / Bronze

Wear Plate : SS-304 (CF 8) / SS-316 (CF 8M) / Bronze

Shaft : SS-304 (CF 8) / SS-316 (CF 8M)

Shaft Sleeve : SS-304 (CF 8) / SS-316 (CF 8M)

Gland Packing : Teflone

APPLICATIONS

MARINE

- Loading and unloading, bilge pumping, washing, fire

fighting, stripping, sanitary duty and circulation.

CONSTRUCTION INDUSTRY

- Dewatering excavation, canals or ponds, ground water

dewatering with well point system or drains, water

supply from wells or canals, hosing down concrete

castings.

AGRICULTURE

- Surface irrigation, liquid manure oxygenation, transfer

and spraying liquid manure or fertilizers, distribution of

liquid animal feed, transfer of must, washing.

INDUSTRY

- Transfer of clean or dirty neutral, acid or alkali liquids

containing sand, mud or solids in suspension, clean or

dirty low viscosity petroleum product or solvents, milk

of lime, caustic soda. - Washing, cooling, circulation, smoke scrubbing,

emergency duty. - Pumping light chemical, sewage, ash water.

- Tiles, marble & ceramic factories, effluent plants.

- Industries for clear water handling at high pressures.

MOBILE MACHINERY

- Cooling water for marine engines and shovels.

- Any application where priming is to be avoided.

WASTE TREATMENT

- Pumping polluted, hot or corrosive waste water

containing sand, mud or solids in suspension, dosing

neutralizing liquids, pumping out se led sludge.

PUBLIC UTILITIES

- For pumping muddy water, sewage, polluted liquids,

solid and in swimming pool. - Dewatering basements, trenches and construction

sites. - Dewatering from basements, multi storey, shopping

malls, godowns etc. - Flood drainage, sewage pumping, fire fighting and

recovery of dangerous liquids.

FEATURES

- Standard design and performance as per

international market. - Less manual intervention with automatic air

release mechanism. - Replacing foot valve by modern technologies.

- Easy availability of Spares.

- Impeller is designed semi opened / opened for

handle contamination. Can handle solid

particles up to 40 mm. - Back pull out design for ease of repair without

disturbing the pipe lines.

- Dynamically balanced rotating parts.

- Long product life

- Motors of mono block pumps are designed to

withstand voltage fluctuation.

(From 180 to 240 volts for single phase pumps)

(From 350 to 450 volts for three phase pumps) - All pumps are available with both Gland

- Packing and Mechanical Seal variants.

Our portfolio includes bare shaft, mono block,

motor coupled and engined coupled pumps.