INDUSTRIAL END SUCTION PUMP (Back Pullout Design)

TECHNICAL CONSTRUCTION

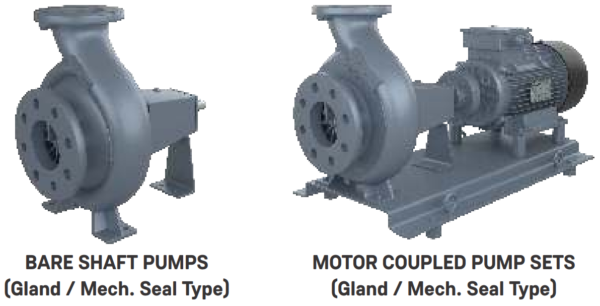

Types : Bare Shaft Pumps

(Gland / Mech. Seal Type)

Motor Coupled Pump Sets

(Gland / Mech. Seal Type)

Motor Hp (Kw) : 0.34 (0.25) to 194.37 (145.00)

Pipe Size (Mm) : 50 X 32 to 200 X 150

Speed (Rpm) : 1450 & 2900

Head (Mtrs) : Up to 145

Discharge (Lps) : Up to 150

MATERIALS OF CONSTRUCTION

REGULAR SUPPLY

Pump body : C. I. Gr. FG 200

Impeller : C. I. Gr. FG 200

Neck ring : Bronze

Stuffing housing : C. I. Gr. FG 200

Bearing housing : C. I. Gr. FG 200

Shaft : SS-410

Shaft sleeve : SS-410

Gland packing : Graphic Asbestos

Mechanical seal : Carbon Ceramic

Bearings : SKF / Equivalent

OPTIONAL SUPPLY

Impeller : Bronze

Shaft : SS-316 (CF 8M)

Gland Packing : Teflone

APPLICATIONS

- Chemicals, petrochemicals, refineries, sugar, paper,

laminates. - Drip irrigation, water supply and building services.

- Condensate handling, fire fighting systems,

environmental. - Thermic fluid, jet dyeing, volatile fluids.

- Corrosive and abrasive process chemicals like acids,

alkalis, solvents, slurries, hydrocarbons, crystallizing

liquids, nitric, ammonia, phosphate, chemical effluents

etc.

- Engineering, marine, refrigeration and cooling tower

installation etc. - Circulation of water in industries, air conditioning

plants, power stations, mine water, lift irrigation,

sprinkler systems, pumping brines, booster services,

oils etc. - Industries, rubber, handling of hydrocarbons, organic

and inorganic chemicals, dm water, food industries,

salt, textiles etc. - Hot and cold water circulation, cooling water

circulation.

FEATURES

The back pull-out design enables removal of the

motor, coupling, bearing housing and impeller

without hampering the existing pump housing or

pipe work.

The pumps are of single stage, single suction,

and horizontal shaft type. The rpm operation

range is 1450 rpm and 2900 rpm at 50 Hz.

This has volute type, end suction casing with top

centerline discharge. Suction, discharge nozzles

and the supporting feet are cast integral with the

casing.

Impeller is enclosed type dynamically balanced.

Shaft MOC is high tensile steel and supported

with anti friction bearings.

Pumps with both Mechanical and Gland seal is

available.

Direction of rotation is clockwise when viewed

from the driving end.

These pumps can be coupled with electric

motors and engines either directly or by belt

drives.

Pumps are available in bare shaft, motor

coupled and close coupling z type design.